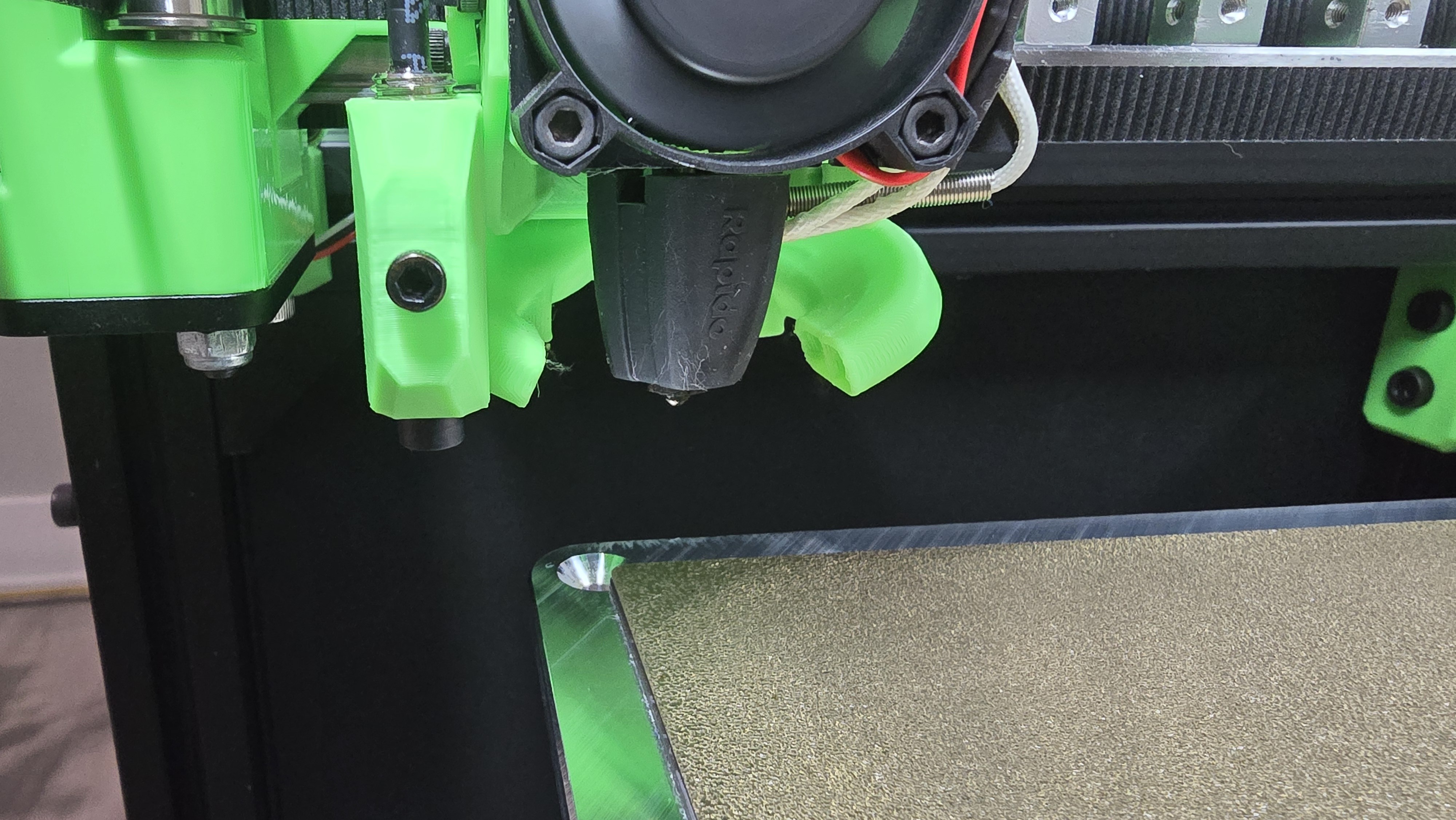

Anyone have any idea what might cause this sort of issue on PLA? I run into it frequently, but pretty much only when all of the following points are true:

- the print has multiple parts, so the extruder spends a decent amount of time off of any given part (only one part from this print is pictured)

- the affected part(s), like the picture above, have a relatively steep outward overhang, extending over the build plate

- the outward overhang part is relatively narrow, as seen from a top view

This is from a printer with a 4028 fan (i.e. pretty massive airflow, server type fan) so even the 35-45% (based on layer time) I have it currently set at is more than 100% with single/dual 5015’s or etc.

I guess my other option is to try supports, but this doesn’t really seem like a situation where supports should be needed. Anyone ever had a similar problem and solved it without just turning the speed waaaayyyyyy down?

I’m not sure I understand. What is it supposed to look like.

this looks like its warping from too much heat. you can try:

lowering temperatures, more cooling or slower printing

also is your bed leveled? sometimes this can happen because the extruder is too close on some points but not on others. from that angle it looks like its not warping evenly.

give us more details about your setup if you can, temps, printer type etc.

This can sometimes be caused by uneven cooling. I was able to resolve it by using a fan shroud that cools on both sides of the print.

Thank you! I should have mentioned this nozzle has a dual fan duct! sides!

I’m seeing quite a few strings there around the nozzle and fan ducts. Another thing that can cause that curling is wet filament, which will also cause the stringing. So you might also try drying it.

Do you see the same curling with other filaments?

Good question! I probably could try drying this filament again, just for kicks…I did dry it not too long ago but it’s probably been long enough that it couldn’t hurt. But yes I’ve seen this issue with virtually every PLA filament I’ve used when the factors I mentioned are all true.

When this failure occurred, I was about 100 filament swaps in (it’s a multicolor print) so faint evidence of the nozzle purging/eject/reload/etc process in the midst of powerful fans is at least initially what I had attributed that to.

From my experience that glitter filament seems to absorb moisture a little faster than some filaments. I keep mine in a drybox all the time.

My Rapido makes fine whispy strings like that when I’m printing too hot, but I’ve never tried PLA on mine.

How fast are you trying to print? Does it behave differently if you slow down?

One of the reasons prints can shrink like this is that the speed is essentially stretching the plastic as it comes out the nozzle, like a rubber band. As the plastic settles that tension pulls it together.

I doubt moisture is the issue, PLA doesn’t actually absorb water very quickly.

Also, have you done a temperature tower and flow calibrarion for this filament?

It’s been a while since I’ve printed but I think both my sidewinder and voron do this. I don’t remember having it after switching to abs. Painted on supports and wider extrusions helped a ton if I remember correctly. Good luck!

Based on your fans it’s more likely too much air + high initial temperature causing uneven cooling. I assume with those fans you’re trying to print really fast?

Well…fast by Ender/etc. standards lol but nowhere near pushing Ratrig performance envelopes here lol. Pretty much stock profile speed wise

From the brown blobs and warping, it’s printing way too hot, which youve probably done to compensate for an overabundance of cooling. Slow the fan, slow down, and lower the temperature.