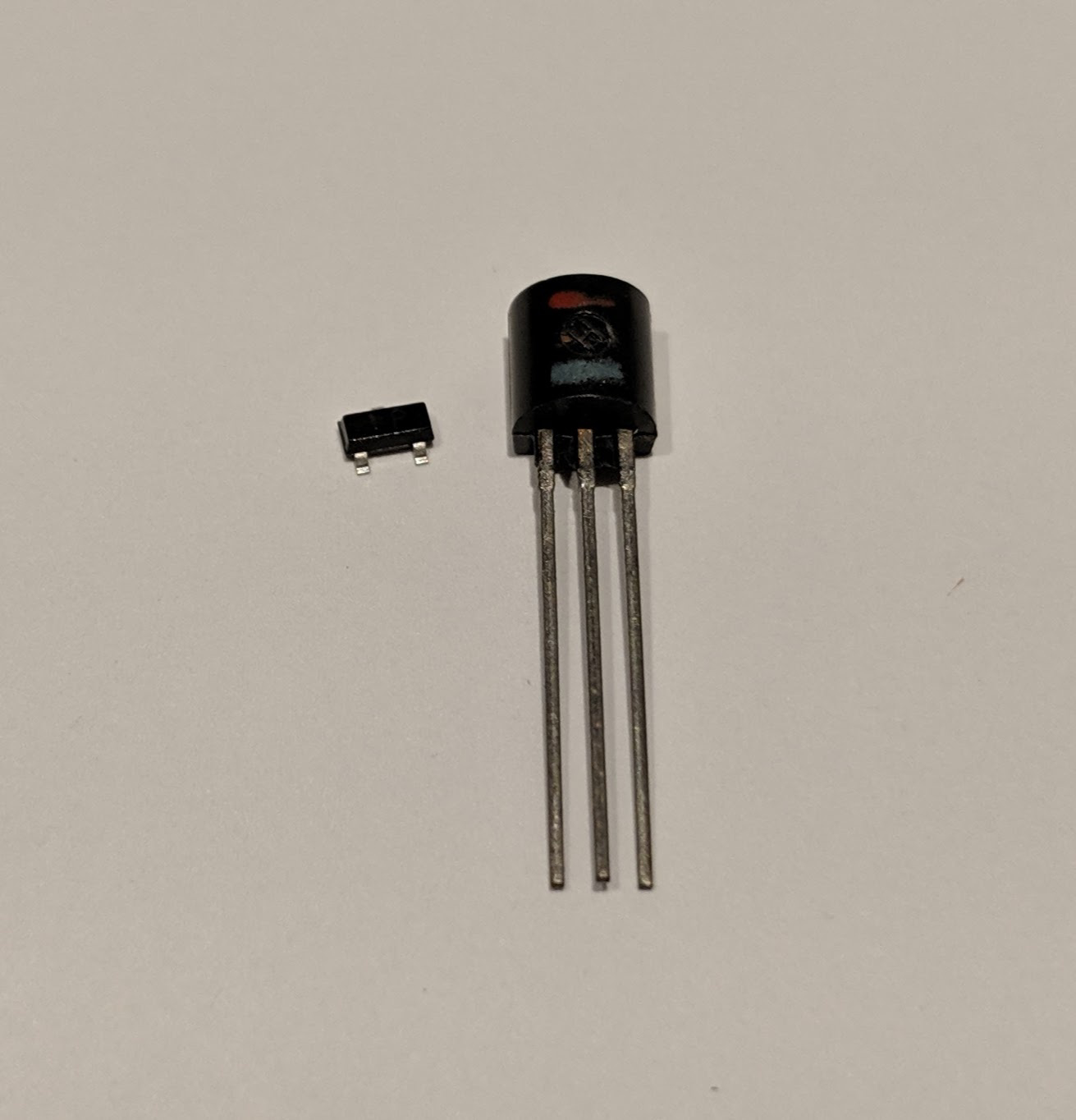

When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

A pair of 2N2222 transistors, one SOT23 and one TO-92.

What do you think of my new distortion pedal?

It’s so…distorted.

I know, right? It’s AWESOME!

I’m fortunate that I have a little straw bale shed behind my house where I have my office. It’s 7’ x 11’ on the inside and I have 4’ x 7’ of one end walled off to form my office and the rest a front room with a futon couch. It is a tiny space but I fit a LOT into it. All you really need is a bin with a piece of hardboard in it to use as a table protector, your soldering iron, and other goodies. You can start small.

I bought a digital scope a while ago. It’s a Siglent SDS 1102CML+. I think it’s 100 MHz but it’s software hackable up to…300 MHz? If you’re going to be doing analog why not buy a used analog scope. I often see HPs and Tectronics on Facebook Marketplace for a couple of hundred dollars. Those are VERY nice scopes and, between you and me, it’s a LOT more scope for the same money as the new digital scopes.